Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,EXW,FCA,DDP,DDU,FAS,CPT,CIP,DEQ,DAF,Express Delivery,DES

Transportation:Ocean,Land,Air,Express,Others

Port:Shanghai,Shenzhen,ningbo

Model:SCT8-55F4

shop dust collection system

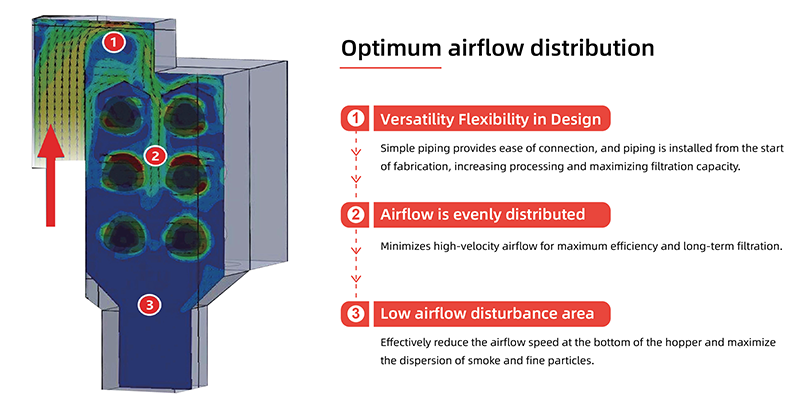

Central Control system implements real-time monitoring and analysis on a number of important parameter of equipments in the operation and show them in the display, and it has self-diagnosis function, showing abnormal and error conditions in the operation of the equipment automatically. The central dust & fume purification system’ s performance is controlled by PLC controlling system.

Vhich SCT8-55F4 is a new design economical industrial dust collector for welding, CNC cutting, polishing and other dust and fume extraction. Industrial Dust Collectors and Centralized Fume Extraction Systems for extraction and filtration of dust, combustible dust, fumes and oil mist, and waste management. Shanghai VHICH's solutions help clean the air, improve working conditions, reduce environmental impact and increase productivity.

PRODUCT CONFIGURATION

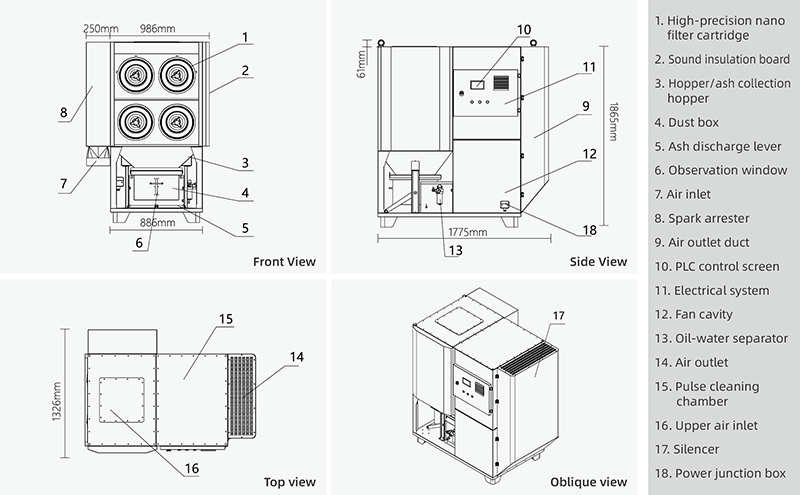

Model | SCT8-55F4 |

Product Name | Industrial Dust Collector |

Core Components | Motor, Plc |

Core Component Warranty Period | 1 Year |

Motor Power | 5.5KW |

Working Voltage | 380V 50Hz |

Air Volume | 4000-5000 m^3/h |

Filtering Accuracy | 0.3um |

Filter Material | Flame retardant coated polyester fiber |

Filter Size & Qty | Dia.324*660mm 4pcs |

Filter Area | 80m^2 |

Cleaning Mode | Automatic pulse back blow |

Noise Level | 75dBA |

Size | 1236*1775*1865mm |

Weight | 700kg |

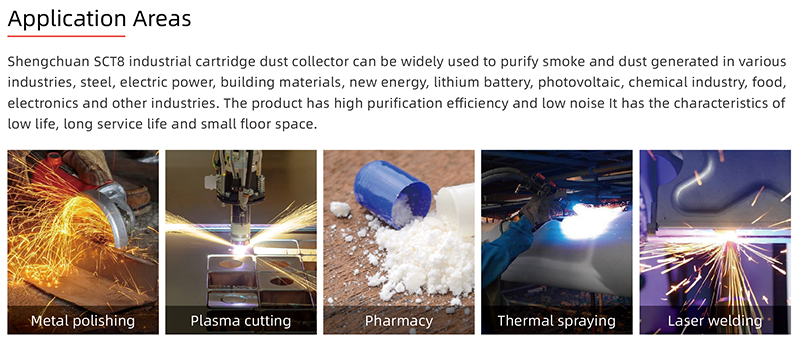

APPLICATION

Laser, plasma, flame cutting,Metal joining, cutting, polishing,Other dust (please ask),Can be installed indoors/outdoors,Dust removal system engineering

1. Product description:

Stationary Fume Extractor is large than Portable Fume Extractor and has large air volume to meet central dust and smoke extraction. It usally used with ducts to form an entire dust and smoke extraction system for welding, CNC cutting, grinding, etc.

2. VHICH Product Series

Portable fume Extractor series:

Stationary fume extractors: (SCT8-850、SCT8-1500)The electric control cabinet can be seperated from main equipment for convenient operation when the main equipment is placed outdoors.

Grinding dust extractors: (SCT5-1000、SCT5-1200)and grinding cabinet (SCT5-2000). The grinding cabinet is usally equipped with telescopic or fixed grinding room, to form a semi-closed space to control dust and smoke spread. It also improves the filtration efficiency with low air volume and energy consumption.

3. R&D

In order to provide advanced products, our R&D department develops 3 to 5 new products every year, and irregularly improves the performance, appearance, and installation methods of existing products.

4. Certification

All our products are approved by CE, ISO9001, ISO14001, utility model patent, design patent, Program copyright, etc.

5. Exhibition

Shanghai VHICH participates at least 5 industry exhibitions each year.

6. Central Fume Extraction System

1) Cantilever type fume extraction system

Cantilever dust removal can be used for manual welding conditions where the work stations are evenly distributed and the span is small. The smoke and dust generated by each welding station can be effectively absorbed at the dust generation point, and will not pollute other parts of the workshop. The skeleton of the suction arm is similar to a human arm and can hover in a space within a certain length. The outer layer of the suction arm is a temperature-resistant hose, which not only prevents the hose from being burned by sparks, but also ensures the flexibility of the movement of the suction arm. A unique rotating structure is designed on the position of the Suction Hood to ensure that the suction hood can be aligned with the welding position in any orientation, so that the suction arm can effectively capture the smoke and dust generated during the welding process. The advantage of the suction arm capture is that it can be close to the place where the smoke is generated, and the collection effect is better.

2) Hood suction type fume extraction system

Cantilever dust removal can be used for manual welding conditions where the work stations are evenly distributed and the span is small. The smoke and dust generated by each welding station can be effectively absorbed at the dust generation point, and will not pollute other parts of the workshop. The skeleton of the suction arm is similar to a human arm and can hover in a space within a certain length. The outer layer of the suction arm is a temperature-resistant hose, which not only prevents the hose from being burned by sparks, but also ensures the flexibility of the movement of the suction arm. A unique rotating structure is designed on the position of the suction hood to ensure that the suction hood can be aligned with the welding position in any orientation, so that the suction arm can effectively capture the smoke and dust generated during the welding process. The advantage of the suction arm capture is that it can be close to the place where the smoke is generated, and the collection effect is better.

3) Room tupe fume extraction system

Room-type dust removal is suitable for the purification of fumes and smoke generated during the production of automated equipment, such as welding robots, welding machines, grinding, grinding and polishing of metal and plastic parts, drilling, thermal processing, cutting and crushing, stone processing, powder packaging, solid particles and various dusts and fumes produced by mixing and processing.

For working conditions such as robot automatic welding, circular seam and longitudinal seam welding, the smoke and dust purifier is installed with the robot workstation, so that the workstation has its own dust removal function. The fume and smoke are effectively collected through equipment components such as pipes and dust hoods. The room-type design prevents the volatilization and diffusion of smoke to keep the air in the workshop clean.

The working conditions with moderate welding workpieces and large amounts of dust and smoke are suitable for room-type treatment solutions. The room type centralized dust dedusting solution is divided into side suction and top suction method dust collecting ways. The appropriate solution can be designed according to the site condition

shop dust collection system

Contact: Tony wu

Phone: +86 13918891309

E-mail: info@vhich.com

Whatsapp:+86-13918891309

Add: Building A1, No.688 North Huan Cheng Road, Nanqiao Town, Fengxian District, Shanghai, China

We chat